-

-

Like what you see?

Let's talk

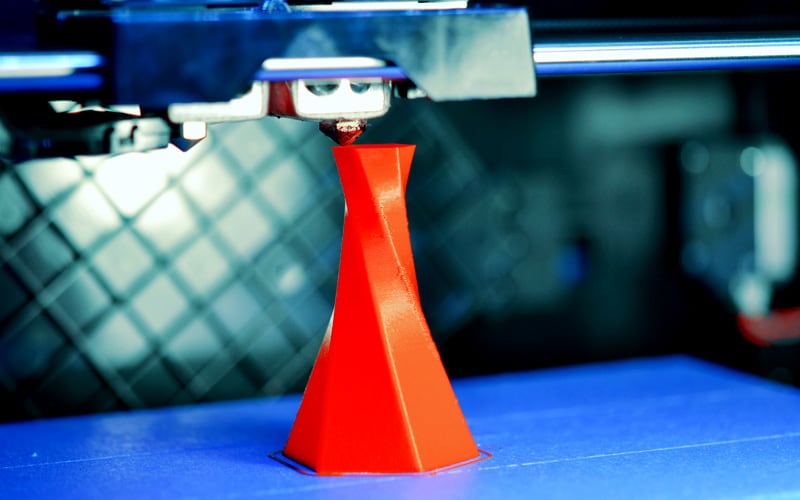

Industry 4.0

The Infosys Aerospace and Defense practice provides an Industry 4.0ecosystem to boost efficiency of avionics systems, aircraft engines, supply chain operations, and the shop floor. We combine Industrial Internet of Things (IIoT) with big data analytics to improve Overall Equipment Effectiveness (OEE). Further, we establish a digital thread to enhance productivity and quality, while minimizing energy consumption and waste.

Infosys transforms brownfield infrastructure and legacy machinery by retrofitting equipment and plants with sensors, Internet / Bluetooth connectivity, virtual / augmented reality platforms, and artificial intelligence-driven systems. The transformation into a ‘smart’ factory drives seamless interoperability between devices and control systems, which optimizes the convergence of digital and physical systems.

Infosys is one of the founder members of the consortium that formulated the acatech Industry 4.0 Maturity Index. It helps manufacturers realize the benefits of IoT-driven industrial applications. Infosys developed the framework, tools and process for Industry 4.0 maturity assessment. We evaluate the as-is state of the assembly station and define a road map for the Industry 4.0 journey. We identify use cases as well as areas of improvement and integrate Industry 4.0 solutions with existing systems.

Infosys Asset Efficiency Testbed, developed in collaboration with the Industrial Internet Consortium (IIC), improves uptime of industrial assets. We track asset utilization, benchmark key performance indicators, and prioritize short-term and mid-term improvement programs to accelerate business value realization. Significantly, digital drawings, work instructions, inspections checklists, and MRO manuals rationalize costs across the asset lifecycle.

Our experts discuss the system architecture of a robust vehicle health monitoring mechanism, and provide a use case to showcase how it addresses functional requirements.

White Paper

White Paper