Overview

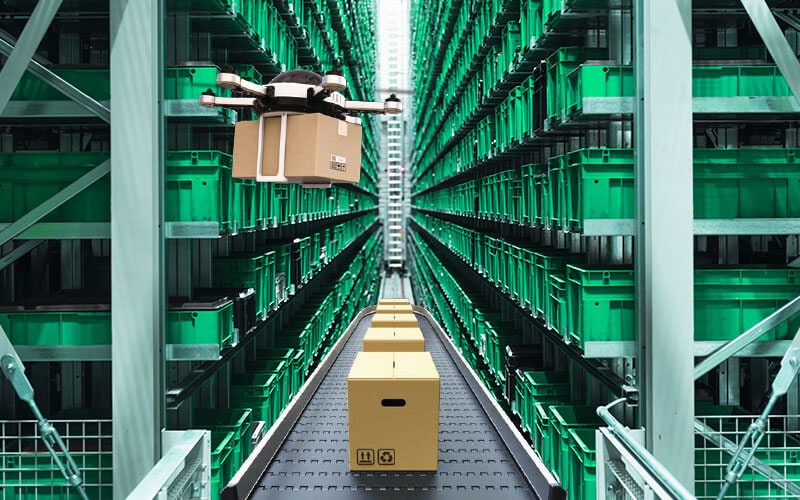

The Infosys Aerospace and Defense practice implements Industry 4.0 to transform the manufacturing landscape. We combine Industrial Internet of Things (IIoT) solutions, big data analytics, and Knowledge-Based Engineering (KBE) practices to improve energy efficiency, minimize idle time, and accelerate time-to-market. Our proprietary engineering services framework for additive manufacturing identifies potential components and assimilates resources for 3D printing.

Our suite of Artificial Intelligence (AI)-based tools and machine learning models help aircraft manufacturers adapt the assembly line and business processes to the R&D / product pipeline. We create a ‘digital twin’ leveraging Augmented Reality (AR), Virtual Reality (VR) and simulators. It helps production managers evaluate critical parameters, including capacity, performance, man-machine-material utilization, and unit cost.

An Industry 4.0 ecosystem drives precision in engineering and maximizes usage of carbon composites. AI tools and modeling provide a cost-effective approach to analyze changes to the layout, equipment and manufacturing plans prior to final assembly. Further, robotic automation and remote inspection techniques enhance quality.

Infosys adopts Value Stream Mapping (VSM) as well as Value Analysis and Value Engineering (VAVE) techniques to save procurements costs, rationalize resource consumption, and minimize machining as well as waste. Our VSM tools help identify bottlenecks in the assembly line through visualization of process flow and interdependence between input / output variables.

Our digital assembly line aligns design, machinery and resources for smooth operations.

talk to our expertsWhite paper: Infosys develops engineering services framework for 3D printing

Our tool identifies candidate aircraft parts for additive manufacturing. A proof of concept demonstrates technical feasibility and profitability.